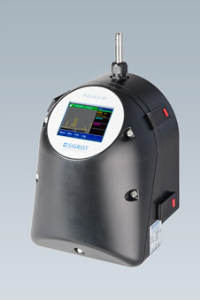

- Well-proven UV-Fluorescence measuring principle

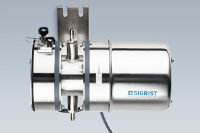

- True non-contact measurement in a free-fall stream

- Dual-beam optics for highest accuracy and stability

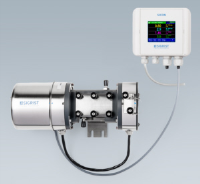

- Integrated operation panel with touch screen, colour display and data logger

- Quick adjustment with secondary standard

- Minimum maintenance requirements

- Correlates to any International recognized standard reference method

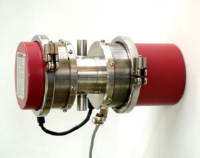

The OilGuard works on the fluorescence principle. The design uses a free-fall measuring system that eliminates contact between the sample and the flow cell. Adoptions to various types of oil are carried out by means of calibration curves, a control glass makes it easy to check or recalibrate the instrument.

|

Measuring principle

|

UV-Fluorescence

|

|

Nominal range

|

0 .. 100 FLU

0 .. 1'000 ppm oil (depending on the oil characteristics)

|

|

Scale ranges

|

8, freely configurable

|

|

Resolution

|

±0.5% (referred to quinine sulphate in water)

|

|

Reproducibility

|

±2% (referred to quinine sulphate in water)

|

|

Reaction time

|

< 2 s (step response => limit switch)

|

|

Installation

|

Online side stream

|

|

Enclosure

|

Sheet steel (ST 1203) with synthetic resin coating

|

|

Protection

|

IP65

|

|

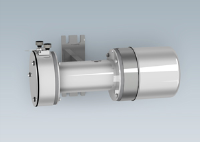

Flow cell material

|

Closed flow cell: stainless steel 316L / 1.4435

Free-fall cell: stainless steel 316L / 1.4435 or PVDF

|

|

Sample flow rate

|

Closed flow cell: 0.5 .. 2 l/min

Free-fall cell: 5 .. 7 l/min

|

|

Sample temperature

|

Closed flow cell: max. 100 °C

Free-fall cell: max. 40 °C (VA), max. 95 °C (PVDF)

|

|

Sample pressure

|

Closed flow cell: max. 1 MPa (=10 bar)

Free-fall cell: pressure-less

|

|

Ambient temperature

|

-20 .. +50 °C

|

|

Humidity

|

0 .. 100% RH

|

|

Supply voltage

|

230 V; 50/60 Hz oder 100/115/130 V

|

|

Power input

|

max. 65 W

|

|

Dimensions

|

70 x 50 x 35 cm (w x h x d)

|

|

Weight

|

37 kg

|

|

Display

|

¼ VGA, 5.7“

|

|

Operation

|

Touchscreen

|

|

Inputs/outputs

|

1 x 0/4 .. 20 mA, galvanic separated

7 x digital outputs, freely configurable

5 x digital inputs, freely configurable

|

|

Interfaces

|

Ethernet, Modbus TCP, microSD-card

Optional: HART, Profibus DP, Modbus RTU

|

| Lowest measuring range |

0-0.3 FLU |

| Highest measuring range |

0-100 FLU |

| Applications in |

Crude Oil Production |

| Petrochemical Industry / Refinery |

| Power Plants |

Oil (HC) Traces after Separator

| Lowest measuring range |

0-0.3 FLU |

| Highest measuring range |

0-100 FLU |

| Applications in |

Crude Oil Production |

| Power Plants |

Oil (HC) Traces in Condensate

| Lowest measuring range |

0-0.3 FLU |

| Highest measuring range |

0-100 FLU |

| Applications in |

Chemical / Pharmaceutical Industry |

| Machine and Metal Industry |

| Petrochemical Industry / Refinery |

| Power Plants |

| Ship Industry |

Oil (HC) Traces in Cooling Water

| Lowest measuring range |

0-0.3 FLU |

| Highest measuring range |

0-100 FLU |

| Applications in |

Chemical / Pharmaceutical Industry |

| Machine and Metal Industry |

| Petrochemical Industry / Refinery |

| Power Plants |

Oil (HC) Traces in Process Water / Waste Water

| Lowest measuring range |

0-0.3 FLU |

| Highest measuring range |

0-100 FLU |

| Applications in |

Chemical / Pharmaceutical Industry |

| Crude Oil Production |

| Emission Monitoring |

| Machine and Metal Industry |

| Petrochemical Industry / Refinery |

| Power Plants |

| Pulp / Paper Industry |

| Ship Industry |

| Waste Water Treatment |

Oil (HC) Traces in Produced Water

| Lowest measuring range |

0-0.3 FLU |

| Highest measuring range |

0-100 FLU |

| Applications in |

Crude Oil Production |

| Ship Industry |

Oil (HC) Traces in Raw Water

| Lowest measuring range |

0-0.3 FLU |

| Highest measuring range |

0-100 FLU |

| Applications in |

Drinking Water Treatment |

| Industry |

Measuring Point |

|

Chemical / Pharmaceutical Industry

|

Oil (HC) Traces in Condensate

Oil (HC) Traces in Cooling Water

Oil (HC) Traces in Process Water / Waste Water

|

|

Crude Oil Production

|

Oil (HC) Traces after Heat Exchanger

Oil (HC) Traces after Separator

Oil (HC) Traces in Process Water / Waste Water

Oil (HC) Traces in Produced Water

|

|

Drinking Water Treatment

|

Oil (HC) Traces in Raw Water

|

|

Emission Monitoring

|

Oil (HC) Traces in Process Water / Waste Water

|

|

Machine and Metal Industry

|

Oil (HC) Traces in Condensate

Oil (HC) Traces in Cooling Water

Oil (HC) Traces in Process Water / Waste Water

|

|

Petrochemical Industry / Refinery

|

Oil (HC) Traces after Heat Exchanger

Oil (HC) Traces in Condensate

Oil (HC) Traces in Cooling Water

Oil (HC) Traces in Process Water / Waste Water

|

|

Power Plants

|

Oil (HC) Traces after Heat Exchanger

Oil (HC) Traces after Separator

Oil (HC) Traces in Condensate

Oil (HC) Traces in Cooling Water

Oil (HC) Traces in Process Water / Waste Water

|

|

Pulp / Paper Industry

|

Oil (HC) Traces in Process Water / Waste Water

|

|

Ship Industry

|

Oil (HC) Traces in Condensate

Oil (HC) Traces in Process Water / Waste Water

Oil (HC) Traces in Produced Water

|

|

Waste Water Treatment

|

Oil (HC) Traces in Process Water / Waste Water

|